Our measuring room is fully climate controlled and is on a separate foundation to prevent vibration. The measuring tools are checked annually by an approved laboratory. All the measuring machines are also checked and calibrated annually. These controls allow us to do measurement work for third parties.

All the certificates for our measuring instruments are available for inspection by the customer. We provide an easy-to-read report containing all the dimensions of interest to you. The measurement report can naturally also show the form and position tolerances (optionally even graphically).

We can also perform reverse engineering: we can reverse engineer with both our CMM and the gear measuring machine. Parts and gears with unknown data can be measured, after which a measurement report or CAD drawing can be made.

We have the following measuring machines:

- Numerex CMM bridge type (3µm + L/400) L1500 W900 H900 with a touch probe system and tool rack.

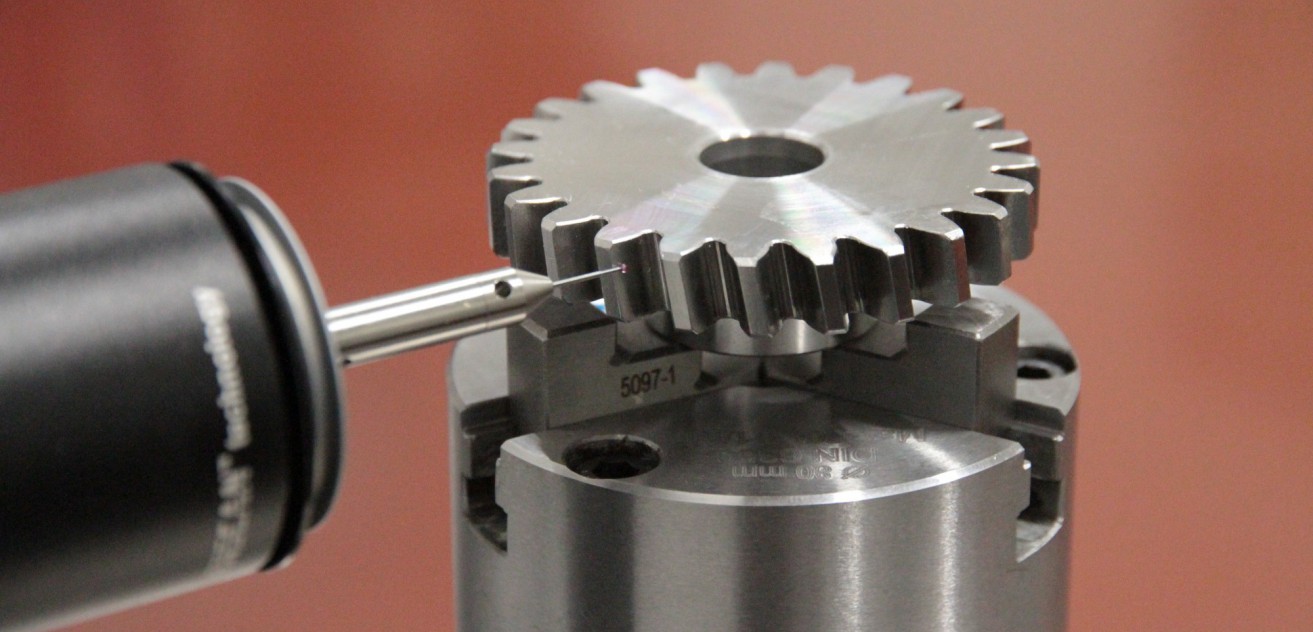

- Wenzel WGT 280 gear measuring machine with which we can scan and measure gears with a diameter of up to 280 mm. The gear measuring machine also has the ability to check shafts with lengths of up to 450 mm.

- Mitutoyo Quick Scope auto-focus vision measuring machine.

- Trimos length measuring bench L1500 used to calibrate measuring instruments.